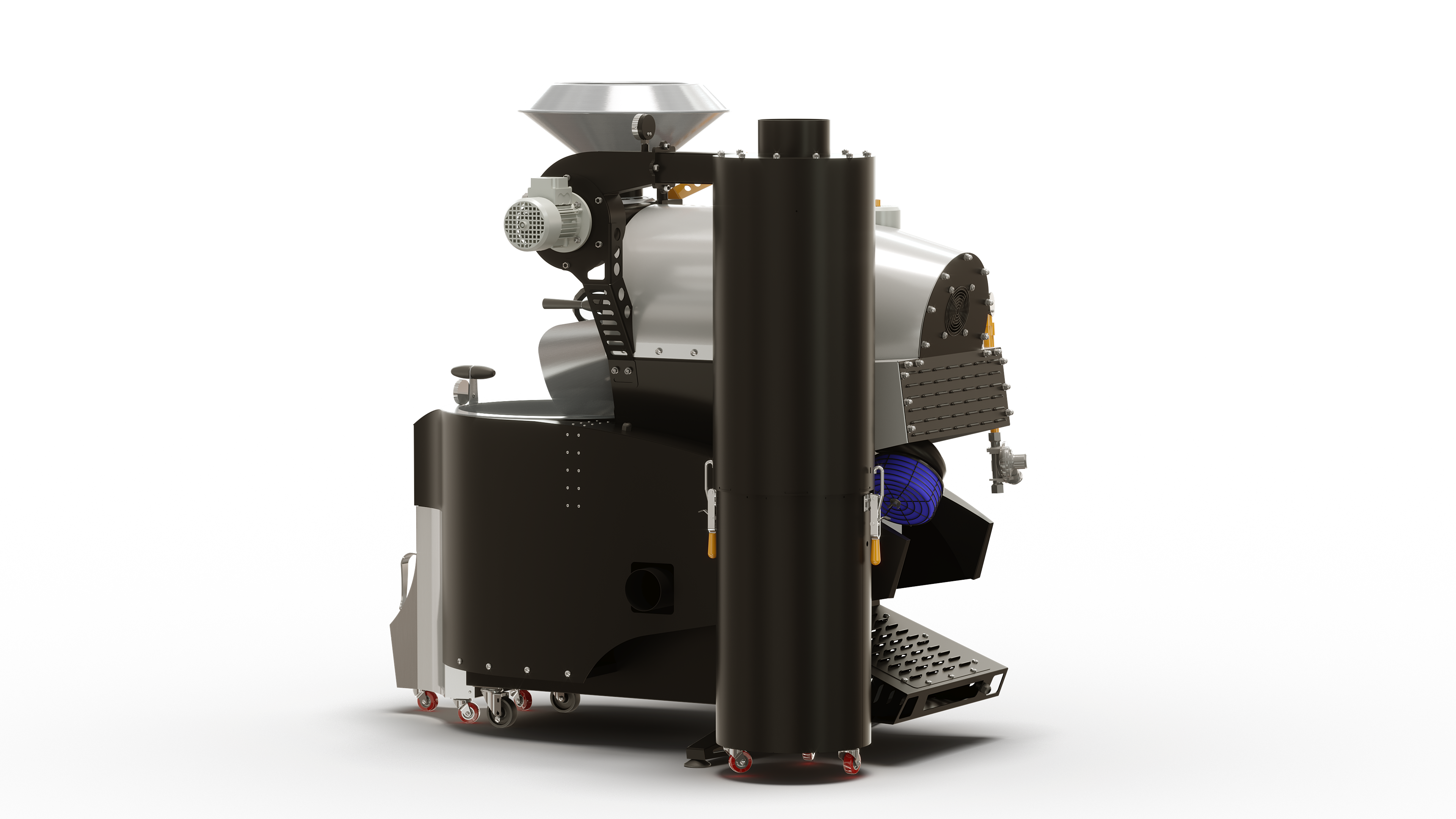

The Silon ZR7, a 7kg batch shop roaster is a work of art.

This time, we dedicate our work to you, the coffee artisan.

Silon means ‘jet’ in Hebrew.

The Silon ZR7 was originally researched and designed as a tool for baristas who craft their own beans, batch by batch, to be served with great professional pride. We envisioned Silon ZR7 for those who deserve the best tool out there. We present you with a roasting machine built to the highest standard in every possible respect: quality in design, quality of build, quality of coffee produced. We crafted Silon ZR7 to be the crown jewel of your coffee-roasting practice, right at the center of your atelier.

The Silon ZR7 is much more than your everyday shop roaster. Loyal to our endless pursuit of excellence, the Silon ZR7 was created, from start to finish, using our long-standing experience in designing state-of-the-art roasters.

As a tool made for pros, we deliver conductive heat closer to the beans than we ever dared to do with any of our previous commercial coffee roasting machines. We feel certain we can grant all due credit to you, the true artisan we aim at. We count on you, the coffee craftsman, so we removed all built-in limitations that are sometimes deemed necessary when considering a commercial-scale machine.

We believe we understand your goals. You work hard to keep your businesses reputation at the top of the scale. You strive to understand the effect each parameter has on the roasting process. You wish to maximize output from each batch of precious beans. When it comes to roasting, just like with driving, you want to go all the way through without ABS. You want to take it right to the edge, very close, but never too far. This means you need to take charge, and to stay fully on top of things. We know you will, because the process will keep you thrilled to explore.

These have been our guiding principles in optimizing crucial parameters:

- Advanced Thermodynamic Characterization: A tightly sealed and controlled ceramic combustion chamber design inspired by our extensive research into conductive and convective heat pathways.

- Robust and Accurate Drum Housing: Ensuring perfect alignment of drum spin throughout the product’s entire lifecycle. Greased hemispherical bearings, zero-tolerance precision dry-slide bearings, and a micrometric mechanism to adjust drum gap ensure the edge of the drum stays perfectly perpendicular to the front plate of the machine at minimal tolerance.

- Drum Proportion: Optimizing ratio of bean mass to metal contact area for a superb conductive thermal dialog.

- In-drum Variable Agitation: Designed for perfect bean stirring, greater heat conduction between metal and beans, effective chaff separation, and immediate evacuation of beans from the drum into the cooling group.

- Monitoring and Control: Monitoring of drum air and bean temperature. Digital control of drum revolution speed, drum blower speed, drum aspiration rate, and the fully modulated pre-mix turbo gas burner.

- Software (optional): State-of-the-art, Israeli roasting management software.

- Perfect Heat Dispersion: A sophisticated heat dispersion scheme involves thermal flow emanating from the heat source located at the bottom towards the top of the structure using secondary airflow propelled by well-calculated jets of air. Specifically designed perforation at the top front end of the combustion chamber allows air to flow in in precise ratio.

- Fully Modulated Pre-Mix Turbo Gas Burner: The Burner is fully controllable from low power to overkill with high frequency of infrared reflection towards the drum. Ultra low NOx specs in infrared flame screen achieve the cleanest, most efficient energy production. No soot accumulation in the drum or harmful CO emission.

A New Generation of Roasting Drums

An extensive, in-depth research and development process has resulted in three distinctive tailor-made drum models for the Silon ZR7 line:

- Silon ZR7 T4 Drum

This solid mild steel drum was designed to produce an extensive aromatic range and high sugar levels during roasting with a higher degree of safe but daring heat conduction. This results in a superb roast for most styles, including blends roasted for espresso. - Silon ZR7 Infrared Drum

This drum is designed to produce a stronger taste with higher levels of caramelized sugars and excels in rapid roasting times. Two separate layers of perforated mild steel, the inner one promoting an improved grip of the beans, ensuring advanced agitation and a larger contact surface area between the beans and the heating source. High frequency infrared radiation emanating from the advanced pre-mix turbo gas burner is applied to the beans via the perforated layers. - Silon ZR7 Thermodynamic Drum

This is the most advanced drum available in today’s industry. Built from two layers of mild steel with a middle layer of pure copper, it has extremely high thermal absorption and heat conduction characteristics. In contrast to standard drums in which roasting is performed by direct, limited contact between the beans and the drum, the Silon ZR7 Thermodynamic Drum exhibits a unique scheme of sophisticated heat conduction applied to a wider contact surface between beans and drum. Heat is transferred via the copper layer creating a 1.4 mm gap between the heat and the beans, removing any risk of burn marks. This drum excels in producing an evenly roasted batch of superb beans, allowing a higher range of temperature operation, and writes its own new language in thermal dialog – just imagine, reflected heat conduction.

Perfect Heat Dispersion

As a result of extensive research, the ceramic combustion chamber is optimally located in relation to the drum. Heat spreads evenly from the machine core throughout the drum. Our design challenges the more common setup you typically find in an open drum housing that involves secondary air poorly mixed with a heat source. In our innovative configuration, the heat source is located at the bottom. Secondary airflow is propelled by well-calculated jets. Heat is collected at the upper end of the structure using the natural tendency of hot air to rise. Flow and ratio are precisely controlled through jets of air that pass through specially designed holes at the top front end of the sealed and isolated roasting chamber. Here you will find no silly vents, shutters, or louvers to keep the flame alive – not with our pre-mix turbo gas burner technology.

Fully Modulated Pre-Mix Turbo Gas Burner Technology

An infrared flame screen is the cleanest, most efficient way to produce energy out of any type of fuel. Ultra low NOx specs fulfill the strictest pollution standards. It may not mean much at this point, but it is all about your health as the operator, your surroundings, and your coffee. No soot accumulation in the drum to coat your coffee, none of the harmful CO produced during operation, no irritated red eyes at the end of the day. Our burner runs the full gamut, at any stage, from low power to overkill, controlled by your choice of either a potentiometer or software, with high frequency of infrared reflection towards your choice of either a solid or a perforated drum.

Fast and Effective Cooling

At the end of the roasting cycle, the entire roasted batch is transferred to the cooling group in a matter of seconds. This external group is made of 100% stainless steel with special food-grade fluoropolymer agitation blades, which efficiently shuffle the beans over the cooling mesh. Aided by a high capacity blower, an entire batch is cooled in less than 3 minutes.

Clean, Efficient and Safe Heating System

Coffee-Tech Engineering’s entire Silon ZR7 line features a highly effective pre-mix turbo gas burner. This clean heat source provides maximum gas burning efficiency with minimum levels of carbon monoxide emission. Safe, economical and stable, it features many unique parameters for control and calibration.

Unique Roasting Software

Silon ZR7 features unique roasting software developed by Coffee-Tech Engineering, enabling the user to predefine and program personal roasting profiles. Each parameter can be mapped out and appropriately adjusted by recording the desired heat curves and controlling the variable drum speed profile as well as the speed of the drum venting blower. This can be done at any stage of the roasting process. Numerous roasting profiles can be applied, again and again, with the greatest accuracy.

Comprehensive Set of Features

At Coffee-Tech Engineering, we pay special attention to the less than obvious details: compact, efficient machine structure, batch cooling time, drum evacuation time, size of monitoring control lens, and drum-gate. These features are often ignored, however, their impact is substantial on the finished brew.

At Coffee-Tech Engineering we test every setting and modification in our laboratory to maximize bean potential. Contributing to the machine’s cutting-edge technology, the roasting process achieves excellent levels of desired coffee properties such as rich sugar content and a wide aromatic spectrum. These spectacular values are reached without burning the “woody” substance of the beans or generating other negative side effects known in roasting.

The Perfect Roasting System

Determining a high level of conductive heat has proven to be the best method for producing a rich cup, and this is where we differ from other manufacturers. Since heat conduction is complicated and presents several unresolved issues, many have abandoned it in favor of convective heat that is much more forgivable in terms of the end result, range of aromas, and shelf life. At Coffee-Tech Engineering, we chose to invest in extensive research in order to solve these issues. In doing so, we are proud to offer a machine that truly reflects our beliefs and understanding of coffee roasting.

The Silon ZR7 roasts continuously, while cooling takes place outside the drum, making it possible to roast up to 28 kg of green beans per hour. The Silon ZR7 features a beautiful, user friendly, streamlined ergonomic design that puts safety first, with quiet operation. Each function has an individual motor and heat protection.

We take great pride in the Silon ZR7 high-end craftsmanship. It is the result of our long-standing expertise in high-end product design and CAD. We are sticklers for high-quality materials and components and use manufacturing tools assembled by Coffee-Tech Engineering’s passionate experts.

The Silon ZR7 is available to order with various heating methods from natural gas and LPG to traditional wood, pellet, charcoal, and coffee processing waste as heating sources. As a high-end roasting machine, the Silon ZR7 will ensure reliable operation as well as consistent superb results for many years to come. By owning it, you truly possess a piece of art, a fruit of passion, an accumulation of years of R&D with no limitations. We can only wish for more chances in life to take on such an endeavor. We do not take it for granted. We are proud of what we accomplished and feel lucky to have made it. We stand by our achievements.